Architecture Section

Two PC technologies expand building construction methods

Prestressed Concrete (PC)

Giving compression force (prestressing force) to concrete which is strong in compression but weak in tension greatly improves the characteristics of concrete. Prestressed concrete makes concrete usable for long spans, high strength and non-crack requirements.

Precast Concrete (PCa)

Precast concrete (PCa) members are produced at factories or similar establishments and then transported to construction sites. Solid and strong structure is built by assembling and post-tensioning precast members using prestressing (PC) tendons.

PCaPC combines two distinctive PC technologies

Precast Prestressed Concrete (PCaPC)

Concrete elements are produced at factories under high quality control. PCaPC contributes to the reductions in labor and construction time. Precast concrete enables unique and elaborate shapes and design of elements which is difficult to achieve by cast-in-place concrete.

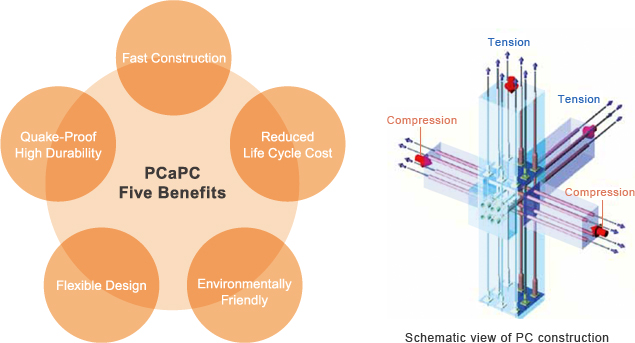

PCaPC creates various benefits in building construction.

- PCaPC enables long spans, large open space and provides flexibility to floor planning.

- PCaPC contributes to rapid construction and labor saving at site.

- PCaPC offers high earthquake resistance. It cuts off maintenance cost as well.

- PCaPC uses factory-made high-quality high-strength members. It improves structural performance.

- PCaPC preserves resources used for construction materials and contributes to sustainable development.