Repair parts with insufficient filling of PC grout (Re-passive Method)

Re-Passive Method

Overview

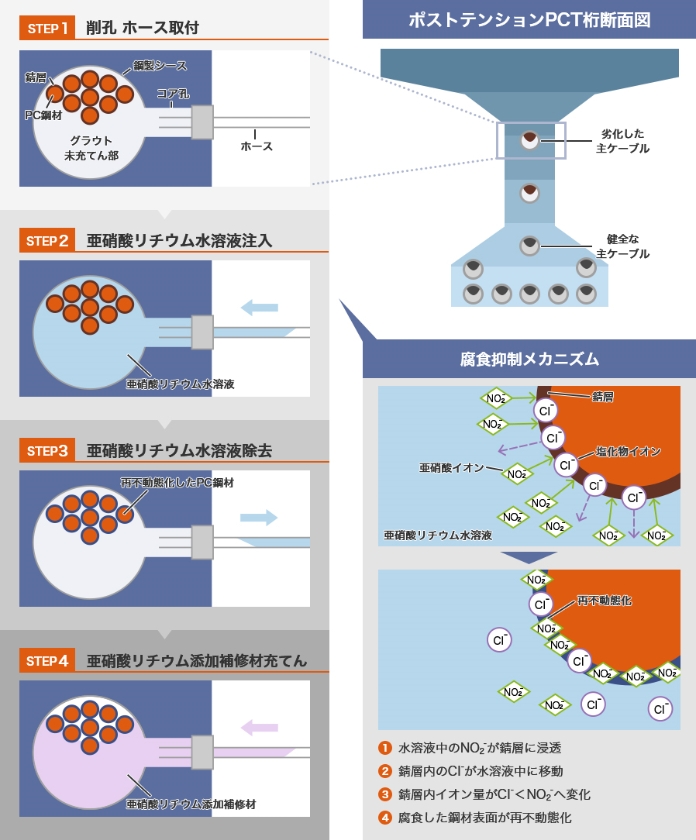

In recently year, it has been reported that the permeation of chloride ions from antifreeze agents into parts with insufficient filling of existing post-tensioned PC bridge can result in severe corrosion of important PC steel, which can lead to the structural unsafety, and in the worst case, the rupture of structures. Re-passive method is a new repair method enable to fill lithium nitrite-added repair material and inject lithium nitrite aqueous solution into corroded PC steel, where good repair effect by conventional grout reinjection method cannot be obtained. The structural safety's reduction is prevented due to reliable passivation and anti-corrosion, and the life of existing PC bridge is extended.

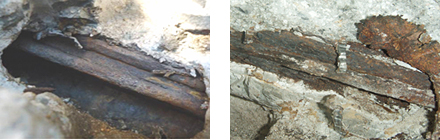

Deterioration example on existing post-tension PC bridge, where this method shall be applied.

Features

- Reliable anti-corrosion effect

- A high anti-corrosion effect can be obtained because the lithium nitrate solution permeate into the rust layer containing Cl- of corroded PC steel at early stage and re-create passive film.

- Monitoring Possible

- By installing a monitoring sensor inside the sheath, it is possible to monitor electrochemically the anti-corrosion effect during and after construction.

- Excellent durability

- The lithium nitrite-added repair material suppresses the diffusion to outside of lithium nitrite, which permeated into the rust layer. As a result, long-term anti-corrosion effect is obtained.

- Reduction of maintenance costs

- Maintenance cost is reduced because the method prevents PC structure from safety reduction and it is not required reinforcement measures as the conventional method.

- Wide range of applicability

- The method is applicable on various PC steel materials used on post-tensioned structure such as main cable, shear rebar, transverse prestressing cable, and steel rebar.

- *The re-passive method is registered on NETIS (Registration Number: KT-120108-VR)

- *This method was developed in collaboration with professor Hidenori Morikawa from Kobe University, and was patented with number 5312526.

Construction Procedure

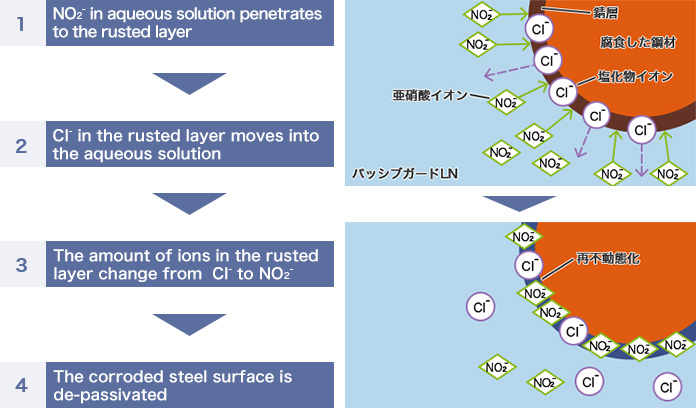

Aqueous Solution With 40% Lithium Nitrite (Passive Guard LN)

Passive Guard LN is an aqueous solution of Lithium nitrite (LiNO2) with a concentration of 40%. Corrosion of steel material caused by carbonization and salt damage can be suppressed effectively by directly coating or immersing on the corroded steel. The solution can also be used as an aqueous solution for injection work to repair parts with insufficient filling of PC grout (Re-passive method, NETIS registration No. KT-120108-VR and patent No. 5312526), and as an addition to the cement type small gap filling repair material (Gap Guard PC).

Advantages

- Reliable anti-corrosion effect

- The lithium nitrate ion (NO2) penetrates into the rusted layer of corroded steal and de-passivate the surface of the steel.

- Applicable to Gap Guard PC as Addition

- The solution can be added to the cement type small gap filling repair material (Gap Guard PC) used for repair parts with insufficient filling of PC grout (Re-passive method).

- Applicable to ASR damaged structures

- Because the solution contains lithium ion (Li+), which has an ASR (Alkali-silica reaction) inhibitor effect, it can also be applied to concrete structures damaged by ASR.

Appearance and Physical Characteristic

| Appearance | Blue transparent liquid |

|---|---|

| pH | 8-10 |

| Concentration | 1.20-1.30 |

Packing

Precautions

Handling Precautions

- Because of the possibility of hazardous gas reaction, do not mix with other admixtures or chemical substance (especially acidic substances).

- Wear proactive equipment such as protective glasses and protective gloves (excluding standard working gloves) before handling.

- Do not construct relevant material by coating spray.

- Wooden material exposure to the solution may cause it to rot or deteriorate to some degree. An appropriate formwork and curing procedure should be taken when using the solution.

- Disposal of the remaining solution and its packaging should done by informing the local government and through the specialized chemical waste disposal service provider.

- Do not dispose the solution into the river.

- Do not damage the container containing this solution

- For storage, make sure to keep the container completely sealed and under the temperature range between 5 to 40 degree Celsius.

- When used for aqueous solution injection work in in cold region, components may precipitate Therefore, for 1 can of L-type package, please make sure to dilute the solution with 2.8kg of purified water in order to use as 35% aqueous solution.

In case of emergency

- In case the solution get into the eye, promptly wash the afflicted eye with clean water for at least 15 minutes and see a specialist.

- In case the skin get exposed to the solution, promptly washed the afflicted area with soap and water. If there is an irritation or abnormal symptom, see a specialist.

- If the solution get on the clothes, change the clothes immediately.

- If swallowing the solution by mistakes, spit it out immediately if possible and see a specialist as soon as possible. Do tell that the swallowed solution containing nitrite compound.

Repair Material for Cement Type Small Gap Filling (Gap Guard PC)

Gap Guard PC is a pre-mixed type cement-based for filling small gaps with the easy insurance for quality. In addition to being able to be used for PC grout, it also can be used for repairing parts with insufficient filling of PC grout (Re-passive method, NETIS registration No. KT-120108-VR and Patent no. 5312526) as a lithium repair material added to aqueous solution of lithium nitrite (Passive Guard LN).

Advantages

- Excellent Small Gap Filling Property

- The gap guard PC has excellent liquidity and is enable to fill up a small gap of about 1mm.

- Long Usability Duration

- The material can be used up to 5-6 hours after mixing.

- Inseparability in Still Water

- The material has an appropriate viscosity and has excellent inseparability in still water.

- Applicable to add passive guard LN

- The specified performance can be ensured even if a 40% lithium nitrite aqueous solution (passive guard LN) is added.

- Applicable to use as PC Grout

- The material can be used as a PC grout material and especially suitable for post- injection materials.

- Premixed Type

- A stable quality can be easily obtained due to its premixed usage.

- High Strength

- Compressive strength equal to or higher than that of high-strength concrete can be obtained.

How to Use

Composition

- The water of 5.75L to 6.75L is used for each can (package) containing 20kg of the material.

- If aqueous solution containing 40% lithium nitrate (Passive Guard LN) is used as addition, for each can of 20kg, one package (S type) of passive guard LN and the water of 7.25-7.75L are added.

- * In winter, the fluidity may decrease faster, so use warm water to control the temperature so that the temperature of mixing water is above 15 degree Celsius.

Mixing Method

- Add gradually the material while rotating a hand mixer with a rotation speed of 1000rpm or more in a container with predetermined amount of water.

- When adding the aqueous solution containing 40% lithium nitrate (Passive Guard LN), mix the passive guard LN (S-type) with water in advance, and then add the mixture to the material.

- The standard mixing time is 3 minutes.

Physical Specification

| Test Subject | Testing Method | Year of Completion | ||

|---|---|---|---|---|

| Gap Guard PC on its own (W/B=31.3%) | Gap Guard PC with Passive Guard LN added (W/B=42.0%) | |||

| Rheology Test | Cylindrical Vessel | Revised JASS Method | 293mm | 289mm |

| Material Separation Resistance Test | Tilting Tube Test | JHS419 | There is no water bleeding or mark observed | There is no water bleeding or mark observed |

| Bleeding Probability Test | Vertical Tube Test | JHS420 | 0.00% | 0.00% |

| Volume Change Probability Test | -0.27% | -0.22% | ||

| Compression Strength Test | JSCE-G 531 | 96.5N/mm2 | 76.7N/mm2 | |

| Salt Ion and Particles Content Test | Calculated upon the material quality specification | 0.169kg/m3 | 0.153kg/m3 | |

Precautions

Handling Precautions

- Please keep in mind that if the material come in contact with water, sweat, or tears, the material will becomes a strong alkali and may irritate the skin, eyes, or respiratory organs or cause inflammation of mucous membranes.

- Be careful not to get the material in the eyes. In case the material get into the eyes, immediately clean the eyes and see specialist.

- Be cautious to make sure the material does not get on the skin.

- Be cautious to make sure the material does not get into the eyes or nose.

- Wear protective glasses, protective gloves, and protective masks when handling the material.

- Make sure that the material is out of children's reach.

Precautions During Storage

- Be careful about humidity when storing the material.

- After opening, store in a vinyl bag.

- Inquiry by phone

-

Please contact us if you have any issues or inquiries

- TEL

- +81-3-6385-8050

- FAX

- +81-3-3536-6936

Reception time: Working days (Monday - Friday) 8:30-17:30

(Except for Saturday, Sunday, public holidays, new year, and corporate holidays)

- Inquiry by form

-

Reception is available 24 hours a day and 365 days a year